Key Takeaways

- Purchase orders are the documents proving the demand of purchasing a product. They are mostly used when large quantities of a product is involved.

- It is important to ensure a smooth purchase process for both parties, buyers and sellers.

- Purchase orders are similar to invoices but they differ in terms of their functions.

- There are certain fields that must be present in any purchase order form.

- Digital solutions are suitable to automate manual purchase order processes.

Buying goods as a consumer is relatively simple. Just think about buying groceries or a cup of coffee. Each item has a fixed price, and sales taxes and other fees are clearly stated at the cash register, usually before you pay. The merchant receives funds immediately, even if you opt to pay later with a credit card.

This streamlined, one-to-one model for commercial transactions is great for merchants and service providers who work directly with the public. Consumers quickly get what they need, and sellers collect payment immediately.

Business to business (B2B) transactions are more complicated. Suppliers, vendors, and freelancers provide services or a high volume of goods with negotiable prices, depending on quantity.

B2B transactions involve everything from a new company website design created by an ad agency to a mining company’s massive shipment of raw metal ore to a manufacturing company.

Sellers may not have goods available immediately when buyers need them. This is especially true for manufactured products made on demand.

As a result, B2B transactions rarely involve payment at the point of sale. Rather, they are billed with an invoice and paid at a later date. Payment for the invoice may be due before or after services are rendered or goods are delivered — it depends on the agreement between the buyer and the seller.

The risks of big business purchases

Sellers always risk losing money if they render a service or deliver goods before getting paid. But the risk isn’t on the invoicing party alone — the company trying to procure goods and services can also run into issues.

Below are some of the most common challenges of procurement.

Scenario 1: The supplier can’t fulfill an order by the date needed

Imagine you’re a lightbulb manufacturer in need of a new tungsten supplier. You locate a company willing to work with your budget and negotiate a better price for its materials.

Meanwhile, your sales team accepts new orders for lightbulbs. Over several weeks, you work with the new tungsten supplier to pin down the exact specifications of the sale and how much you can pay.

However, when you receive the invoice, you find out the supplier won’t be able to deliver the agreed-upon material for several months — well past the date you’re supposed to deliver lightbulbs to your customers. Suddenly, you go from expecting a massive windfall profit to being unable to fulfill orders.

Scenario 2: The supplier changes the price

Vendors can also alter prices after the first order. For example, you may want to try out your new supplier’s tungsten before you commit to them as your primary vendor.

They give you a great price on the first 100 pounds of material. The product turns out to be amazing, and you decide to work with them again. However, when the supplier raises prices for the next 100 pounds of material, the new numbers don’t work with your budget. Now you’re in a bind because you have to find a new supplier and start the process all over.

Scenario 3: Your company misallocates funds

Say negotiating with the new tungsten supplier takes a long time. Meanwhile, other company leaders are negotiating deals for other raw production materials — and closing fast — without effectively communicating these new financial obligations to the rest of the company.

By the time you agree on a price with the tungsten supplier and receive the invoice, you no longer have the funds to pay, simply because no one in your company tracked new financial commitments.

Scenario 4: You and the seller don’t communicate clearly

Another danger of relying only on invoices is that the negotiated terms can get lost in the shuffle.

You may spend a great deal of time discussing price points and order quantities with a seller to find an arrangement that works for both of you. However, the invoice may not reflect some of these final details, resulting in the seller backing out of the order and ruining an otherwise fruitful business relationship.

Purchase orders to the rescue

Procuring goods can be a tricky endeavor, and you want to make sure you do it the right way. You need a system that clarifies what’s being purchased and for what price, is approved by internal decision-makers, and streamlines documentation of financial commitments. A system like this not only helps your business operate more efficiently but also helps your vendors as well.

A purchase order (PO) is the best way to smooth procurement. POs help organizations document sales terms before an invoice is prepared and payment is expected. Purchase orders ensure procurement follows a simple and manageable process — one in which stakeholders approve orders before they’re placed.

In the following guide, we’ll go over what a purchase order is as well as the different types, how to create them, and digital tools to manage them.

What is a purchase order?

A purchase order is a document businesses create to outline what they want to buy from a seller. Businesses use purchase orders when they order large quantities.

Similar to a shopping cart on an e-commerce site, a purchase order lists the items the business wants to procure, the quantity, the delivery date, the payment terms, and the delivery method. Once a buyer sends it to a seller, and the seller signs it, the purchase order becomes a legal agreement that serves in place of a contract.

Purchase orders protect both the buyer and the seller. On the buyer’s side, the purchase order guarantees the specific price and delivery terms they’ve negotiated. This prevents the seller from raising the price when they send an invoice or deliver late.

On the seller’s side, the purchase order guarantees the buyer’s commitment to purchase, so the seller doesn’t assume much financial risk when they produce or prepare an order because the buyer can’t back out before paying.

Creating this document helps formalize the negotiations and finalize the agreement between buyers and sellers. Sellers can use purchase orders to understand exactly what’s expected of them as well as project their incoming revenue.

Purchase orders help buyers create an approval workflow so key decision-makers are included in negotiations to ensure that prices fall within budget parameters. That way, there are no surprise charges or cancellations after an invoice is submitted.

Why are purchase orders important?

Purchase orders protect your company and your revenue, keep internal decision-makers on the same page, and streamline transactions with your vendors. They outline every aspect of an exchange, and that kind of clarity is the basis for a good customer-vendor relationship.

Put simply, making and managing purchase orders is more than worth the hassle of creating more paperwork. Here are some of the biggest benefits of purchase orders.

Help operations run more smoothly

Organizations use purchase orders to formalize spending approval workflows. A PO engages decision-makers, appropriate department heads, and other stakeholders in communication about purchases. This communication prevents purchases from going over budget or conflicting with each other.

Every stakeholder has their own experiences, knowledge, and areas of expertise. Bringing all of that together can help an organization make the best purchasing decisions and get the best deal.

Track expenditures

Purchase orders are great budgeting tools as they earmark funds that haven’t been spent yet. When individuals buy something at a store, they receive and pay for goods immediately. However, in business transactions, an organization may have to plan for purchases it won’t make for months.

Purchase orders help ensure businesses keep enough money in reserve to avoid overspending in other areas. This is especially important for operation-critical purchases, such as raw materials for manufacturers.

Purchase orders also show how expense funds are allocated, allowing finance professionals to compare and contrast purchase orders for different vendors.

Create a detailed paper trail

Like an invoice, purchase orders outline how many goods were purchased, how much they cost, and when the order was placed. However, purchase orders provide even more information that’s useful for internal and external audits, such as delivery dates and other details not relevant to payment.

Purchase orders create a paper trail about who approved a particular purchase and when. Because buyers can reference the delivery date on the purchase order when goods arrive, POs can help buyers assess vendor performance as well.

Streamline invoicing

Purchase orders and invoices represent two sides of the same transaction. Sellers request payment with invoices; buyers request goods or services with purchase orders.

Purchase orders make it easier for sellers to create invoices — the seller’s financial team can simply plug the numbers into their invoice template. Buyers later check that an invoice number matches the purchase order number. It’s easy to compare the approved purchase order with the seller’s invoice to make sure the requested funds match the agreed-upon prices.

Legally binding

Purchase orders are much easier to create than a long-form contract, but they offer just as much legal protection. The document protects sellers from buyers who fail to pay or try to back out of an order they’ve already placed. It also protects buyers if a vendor doesn’t deliver as expected. Failure to perform according to PO terms puts one or both parties in breach of contract.

How do purchase orders differ from invoices?

As previously mentioned, purchase orders and invoices play a role in every business transaction.

Sellers submit invoices that match purchase order information at some point during the process to collect their payment. Until the seller submits the invoice, they can use the purchase orders they’ve received to track their expected income and estimate revenue.

There’s no purchase order vs invoice debate as both are appropriate for every transaction — which one an organization uses depends on its role in the sale.

Types of purchase orders

Depending on what they’re trying to procure, companies can use four different types of purchase orders. The variations aren’t substantial, but they can help ease purchasing processes and document important information.

Here are the four most common types of purchase orders.

Standard

As the name implies, this is the most common PO type. It’s also the easiest and most straightforward to understand.

Standard purchase orders are usually drafted when an organization is making a one-off purchase for goods and services. They outline the specifics of what the buyer is trying to procure, the desired quantity, the price, and the delivery date.

Once a standard PO is submitted to the seller and they accept it, the seller is required to fulfill the order, and the buyer is obligated to pay.

Standard purchase orders are usually drafted as needs arise. For example, if the printer at the office breaks, a manager would draft a standard purchase order to replace it.

Standard purchase orders can also be used to restock supplies that periodically run out, such as printer paper or staples. Submitting standard purchase orders for these items on an as-needed basis prevents your company from overspending on supplies and storing too large a stockpile.

Planned

Planned purchase orders are similar to standard purchase orders with one key difference — everything about the order is known except for the delivery date.

This type of recurring purchase order is great for procuring items you need on a regular basis. If your organization tracks how often you run through supplies like printer paper and staples, a planned purchase order would make more sense than a standard one.

A planned purchase order is great for locking in a set price with a supplier for an extended period, without committing to a bulk purchase up front — for example, when printer paper is used at a predictable rate.

This helps buyers budget for their recurring expenses and helps sellers estimate how much revenue they might generate from a single customer in a given period.

Blanket

A blanket purchase order is the most flexible type of procurement agreement. It’s useful for situations in which a buyer knows they will need to make a particular purchase at some point, but the quantity and delivery date are uncertain.

Blanket purchase orders are ideal for buyers who need to purchase goods or services on a recurring basis but in variable quantities and at random times. Like a contract, a blanket purchase order has a specific start and end date. Buyers lock in a set price with the seller, while the seller is assured that the customer will work exclusively with them for a set time frame.

Contract

A contract purchase order is a formal agreement between a buyer and seller. It offers the most protection to both. The contract purchase order outlines legally binding terms and conditions but doesn’t establish delivery dates, quantities, or even the full list of products.

Usually, a contract purchase order creates a framework through which standard or planned purchase orders can be made. It’s used when very high volumes of goods will be purchased over a long period of time, such as between a retailer and a manufacturer.

For example, if a small manufacturer secures a relationship with a big-box retailer like Target or Walmart, sales to that one retail customer will likely comprise all or much of the manufacturer’s revenue. The contract purchase order will outline how much volume the company will be expected to deliver to the retailer and how much it will be paid. This will help the manufacturer budget operations.

On the other hand, the retailer will know how much to expect from the manufacturer in the future. This minimizes the risk of setting aside a lot of shelf space for a particular item but not having enough merchandise to fill it if the manufacturer can’t meet the needed quantity.

How vendors fulfill purchase orders

In an ideal world, vendors would always have cash on hand to create materials at the proper time. However, this isn’t always possible.

For startups just getting off the ground, the only way they may be able to generate revenue is by selling products. However, this won’t be possible without goods from other suppliers, putting them in a catch-22. Similarly, an established seller may not have cash on hand to move into a new goods market they know they can excel in.

That’s where purchase order financing comes in. Suppliers ask third parties to completely or partially fund a customer’s purchase order with the promise of paying them after the sale is completed. Those third parties may even establish a separate deal with the buyer to cover the terms of the sale.

Now that we know what a purchase order is and the different types of POs, let’s go over how purchase orders are carried out.

How to execute the purchase order process

On the surface, a purchase order is a simple document that outlines the important details of a transaction — the seller and buyer, the quantity of items the buyer wants to purchase, price, payment terms, and delivery conditions. It legally protects both parties and facilitates communication between them to streamline the sales process.

But a purchase order does much more than that. Its creation and management provide the framework for a complex approval workflow ensuring that all decision-makers are consulted on purchases and that the buyer gets the best deal possible.

This workflow is the purchase order process — the standard way for small, medium, and large organizations alike to procure goods and services.

What is the purchase order process?

Put simply, the purchase order process is another way to describe the purchase order workflow, which covers researching vendors, drafting a purchase requisition form for internal approval, dispatching a purchase order to sellers, accepting delivery, remitting payment, and closing the sale. In between, the process also includes budget checks, negotiations, and quality checks.

In a streamlined process, company stakeholders review budgets and prospective purchases and clearly communicate expectations to sellers. This process varies from organization to organization, but for most, it consists of the following steps.

Identify the need

The purchase order process begins when an organization needs something — replacement office supplies, new equipment, or raw material to manufacture products. The need could also be more abstract, such as finding a solution to improve communication with remote workers. Someone within the organization conducts research and sets a goal and plan for the product or service needed.

Find a seller

Stakeholders research different vendors to find variations of the products or services they need, compare quality and prices, and consider other elements that could factor into a purchasing decision.

Create a purchase requisition

The first step of creating a purchase order is drafting a purchase requisition, a formal document created by a team member from the buying organization to outline exactly what it wants to purchase.

This document kicks off the purchase order approval workflow. Managers review the purchase requisition and check the budget to see if money is available to cover it. If they approve the purchase, the finance team earmarks funds to pay once they receive the invoice.

During this internal review process, decision-makers may consult with each other or outside sources to get clarity on the value of the goods they’re purchasing and investigate whether it’s possible to get a better deal. There is no significant difference between a purchase requisition and a purchase order except the former is used internally while the latter is sent to vendors.

Dispatch the purchase order

Once internal decision-makers approve a purchase, the organization submits a purchase order to the selected vendor via its approved method of communication. Most prefer to receive purchase orders through email or online forms, but many still accept purchase orders via fax and snail mail.

Wait for seller review

Once the seller receives the purchase order, they review the document to confirm they have the goods available, can deliver on time and according to outlined expectations, and agree that the pricing is accurate.

The seller review may initiate a negotiation process during which one or both parties try to get a better price, change the quantity of products, or modify other elements of the potential sale. If any changes are made, the buyer submits an amended purchase order with the updated terms.

Form an agreement

Once both parties agree on the terms of the purchase order, it becomes legally binding. Sellers may confirm the purchase order with a signature or simple email acknowledging the agreement.

Others may opt to create a sales order document and send it to the buyer to confirm the purchase. A sales order is a commercial document prepared by a vendor and issued to the buyer confirming that a transaction has been approved and the vendor will sell the outlined goods or services.

A sales order is a kind of pre-receipt. It reiterates many of the points included in the purchase order, such as goods or services being purchased, quantity, price, and delivery details. The primary difference between a sales order and a purchase order is that each is used by different parties in the transaction. However, both document the sale to clarify intent and keep teams organized.

Accept delivery

Once an order is ready, the vendor delivers the goods or services to the buyer by the agreed date and under the agreed conditions. If the vendor fails to do this, it’s in breach of contract.

Consequences vary based on the severity of the violation and its impact on the buyer. Even though the purchase order and all other documents involved in this process legally protect the buyer, it’s still up to them to engage attorneys and take other actions to resolve a dispute. Of course, all parties involved in a transaction want to avoid this.

Once the buyer receives the delivery, they conduct a quality check to review the goods or services. For goods, this includes an inspection of the physical products for defects. If any are found, the buyer notifies the vendor to request replacements.

For services, the buyer reviews the work completed to see if it was done according to specifications. For creative work, such as website design or content creation, the buyer may have several rounds of notes for the service provider to implement before the job is completely done.

Close the purchase order

Once the order is complete, the seller closes the purchase order, drafts an invoice, and conducts an internal approval process to make sure it aligns with the purchase order before sending it to the seller. The invoice includes a deadline for payment. Oftentimes, this deadline was agreed on earlier.

Invoice payment

The purchase order process is complete once the buyer remits payment according to the terms outlined in the invoice. If they fail to do this, they are in violation of the sales agreement, and the seller is entitled to pursue legal recourse if the matter isn’t resolved soon.

How to build a purchase order process

Purchase orders are a regular part of every business. Setting up a workflow for them can help your company run more smoothly and save everyone on your team lots of headaches. Regardless of what your organization needs to purchase, these are the general steps to set up your process.

Create purchase categories

Every organization and department within it has different purchasing needs. A run-of-the-mill office periodically needs to replenish supplies such as printer paper and staples. Manufacturers regularly need raw materials to make new products. Equipment at any size and type of business eventually breaks down and needs to be replaced or upgraded to improve efficiency and productivity.

Define categories for the different types of purchases your organization may have to make and create rules for how employees should procure them.

Map out the process

For each of the categories, determine what steps employees should take for procurement. This can include the broad steps for creating purchase orders, as well as if-then conditions related to cost, quantity, and other factors that can alter the approval workflow.

Prepare to spend some time refining this process. It’s likely to change as new employees find better ways of doing things or methods of communication become more advanced. For example, any purchasing process that includes instructions for faxing a purchase order is probably out of date.

Assign roles and grant authority

Follow guidelines established by other approval workflows to decide which employees have the authority to create purchase orders, approve requisitions, and manage the overall process. Always be sure to include the finance team.

Where possible, outline the order in which managers grant authority, and create if-then conditions to regulate who conducts approvals under unusual circumstances, such as when a purchase is above $10,000 or the accounting manager is on vacation.

Automate the process

Paper purchase orders are a thing of the past. Digital tools make it easy to create purchase orders online, get them approved by stakeholders, and submit them to vendors, all without ever printing anything. We’ll learn more about this in Chapter 5.

Test the process

Once you’ve designed your purchase order workflow, be sure to test it with the employees involved before finalizing it. Their feedback will confirm you haven’t missed any crucial steps.

By having your employees test the process, you can enlist them to help find bugs or otherwise make improvements to the workflow. After all, they know the challenges that come with procurement and purchase orders better than anyone else and will be best suited to improve the process.

Why a purchase order process is important

Workflows are the lifeblood of every organization. An effective purchase order process for procurement replenishes supplies and goods almost automatically. Here are a few reasons a well-designed purchase order workflow is important.

Keeps communication open

No matter how small, purchases affect a company’s budget. A purchase order process keeps stakeholders on the same page about what’s needed and what their financial commitments are for each quarter or year. A good process helps stakeholders maintain their budget so they know how much they have to spend.

When budgets are limited, purchase order processes can bring decision-makers together to prioritize what needs to be purchased now and what can wait until more funds are available. This sets a standard for communication and allows teams to work together more efficiently.

Improves planning

A purchase order process helps finance teams stay organized and control expenses instead of rushing to pay invoices. It also helps organizations keep better track of their inventory, so information about quantities isn’t miscommunicated or lost in the shuffle. Operations managers can also better prepare for incoming goods when they are aware of upcoming deliveries.

Builds better business relationships

Properly executed purchase order processes keep buyers and sellers on the same page about what’s expected and for what price. Having these details in writing — with procedures for approval — curbs miscommunication that might otherwise sour a partnership. In addition, purchase orders legally protect both parties in a transaction, a valuable element in a good business relationship.

Ensures compliance

No matter how large an organization and its revenue, budgets are always limited, and expenditures must be properly authorized. When the process is automated, managers can easily verify they aren’t breaking any laws. Transparency in the process also prevents accidental or intentional purchase fraud.

Increases efficiency

Workflows streamline everyday business processes by eliminating guesswork about what actions to take. This ultimately improves efficiency and frees up time for employees and teams to focus on bigger, more important work.

Now that we know more about the purchase order process, let’s take a look at the forms that make up that process.

How to create a purchase requisition form

As we’ve discussed, a purchase order is much more than a document. It provides the foundation for approvals, outlines delivery requirements, and kicks off negotiations. Some businesses have employees prepare a purchase requisition to internally approve spending before sending a purchase order to a vendor.

But how do you prepare purchase requisition forms? Because of their similarities, requisitions can include much of the same information as purchase orders. In this section, we’ll look at the details these forms should include, as well as different ways to create them.

The elements of a purchase order

You should have standardized templates for purchase requisitions and purchase orders that convey all the relevant information about an order to the seller. Here’s what they include.

PO number

Similar to an invoice number, the purchase order number can be based on any numbering system your company uses. The finance or procurement team can even randomize the PO number. The most important thing is that it’s unique to each purchase order, so you or the seller can easily identify the document.

Purchase order date

This information helps with filing, as well as assessing the cycle time of order placement.

Vendor’s name and billing address

The vendor name and billing address help your procurement team easily identify each purchase order without having to look up the PO number. Many companies organize purchase orders, invoices, and other procurement documents by vendor, so having this information readily available helps with filing. The billing address tells your finance team where to remit payment.

Buyer’s name and address

Putting your organization’s name on the requisition form makes it easier for sellers to keep track of your purchase order without referencing the PO number. Like you, they may prefer to organize their files by customer, so this will help facilitate that process. The address will also help with delivery.

Contact information

Additional contact information, such as email addresses and phone numbers, should always be included.

Delivery date

Including the desired delivery date on the requisition form helps the seller determine if they can sell to you. If they’re unable to make the expected delivery date due to quantity shortage or other issues, they’ll begin further discussion and negotiation to find a solution that can work for both parties.

Shipping method

Different delivery speeds require different shipping methods. For example, if a company needs a delivery overnight, the buyer would have to send it via air. Some buyers’ specific shipping requirements can be handled only by certain carriers. If this is the case, specify the delivery method in the form.

Shipping terms

Sometimes, buyers have specific shipping terms based on their intake capacity and other factors. For example, the delivery address may be an office building instead of a facility with a loading dock. Therefore, it would be best for large shipments to be delivered in smaller boxes rather than on a palette that requires a forklift to move.

This part of the requisition form can also dictate related terms, such as a cap on shipping fees the buyer is willing to pay.

Item name, quantity, and other specifications

List the name of each item you want to purchase, matching the name the seller uses to describe their goods. Include the number of units you want of each item as well. If you need to include any additional technical information (say for customizable products), add this information under the item name.

Unit cost, taxes, and total price

Similar to an invoice, list the cost of each unit and the quantities you need in the same row, adding the total for each product. Add taxes and calculate the total price.

Including all of this information makes it easier for your finance team to track their expenditure commitments before they get the invoice. This will also make things easier for the seller, as they can pull this information directly from your document when they draft their invoice.

Payment terms

Include details about when your company pays invoices. If the buyer’s schedule differs greatly from the seller’s, the two parties may have to work out a compromise.

Best online form builders for purchase orders

Many procurement officers want to know how to fill out a purchase order faster. The problem is so common that many online form builders now offer a solution. Some are even free. These are some of the best online form builders for creating purchase order forms and purchase requisitions.

Jotform

Jotform offers more than 10,000 customizable form templates — more than any other online form builder in the world — including dozens of purchase order and purchase requisition form templates.

The intuitive interface and ease of use make Jotform a great alternative to Google Forms — particularly since the latter isn’t able to collect e-signatures. Jotform boasts several widgets that add helpful functionality to forms, including an e-signature widget and a random value generator that auto generates PO numbers.

Google Forms

Originally part of Google Surveys, Google Forms proved so popular that the company spun it off into a standalone product. Now it’s one of the most popular and robust form builders in the world, available in the cloud and free for any Google account holders.

Google Forms makes it easy to build purchase forms and add your branding. Each file can be duplicated endlessly as a template and used to make any type of purchase requisition document. Users can even submit a Google Form purchase order directly to managers for review and approval.

Microsoft Forms

Inspired by the cloud-based functionality of Google Forms, Microsoft Forms makes it easy for users to build surveys, quizzes, and, of course, purchase order forms.

The interface allows procurement officers to create their own fields and pre-populate fields with common items ordered from vendors. This can further streamline the purchase order process as organizations can create templates for each seller they work with and tailor them to their specific needs.

Formsite

Formsite offers many of the same capabilities as Google Forms and Microsoft Forms and is prized for its encryption and ability to protect sensitive information. It may be an ideal solution for industries requiring an unusual degree of IT security, privacy, or discretion.

The form builder uses a drag-and-drop interface so building dynamic forms is a fluid process. The toolbox comes with more than 40 item types and supports many graphic and visualization capabilities, which could be useful for creating purchase order forms for complex orders.

Next, let’s look at other tools that make the purchase order process easier to manage.

How technology helps companies optimize their purchase order processes

Online form builders are just one of the tools that make the purchase order process more efficient. Purchase order software streamlines and automates procurement workflows. Before we talk about the impact these solutions can have on your organization, let’s learn more about what they do.

What is purchase order automation?

Purchase order automation uses software to customize and manage a company’s purchase order process without any paper and with minimal manual engagement. These programs digitize every aspect of the approval workflow, including purchase requisition form drafting, managerial reviews, and even final submission to the vendor.

Without automation, this process requires workers to deliver several paper versions of the same form and hunt down managers who haven’t approved them. With software, the process pauses only for necessary inputs from users.

An automated purchase order workflow proceeds in the same fashion as the manual process, but much faster and with less effort.

Users typically draft unique purchase orders from templates in the software program and then submit them to their managers for review. The system automatically generates an email or other notification to inform managers they have a purchase order to approve.

To batch approvals, purchase orders may collect in a queue, so managers can review them together. The manager then approves or denies each purchase order with the click of a button.

If they deny a purchase order, the system automatically notifies the submitter. Sometimes, the notification comes with manager feedback to implement. Once the purchase order is approved, the system automatically sends it to the vendor for review.

In addition to these features, purchase order software also generates valuable reports in real time that help users make better decisions. Many of these programs calculate annual or quarterly spending based on processed purchase orders or display how much of an allocated spending budget is left.

The challenges of manual purchase order processing

Manual or paper-based purchase order approvals are much more cumbersome than automated workflows. These are just some of the reasons a company may choose to automate:

- Their paper-based purchase order process takes too much time.

- They use too much paper.

- Emails with purchase orders attached take up too much memory or get lost.

- Managers often forget to notify employees when they have approved a purchase order.

- The system lacks visibility or an efficient way for people to check the status of an order they submitted.

How purchase order automation saves money

Upgrading your purchase order process with software completely transforms your company’s procurement process, saving your company time — which translates directly into money. Here are some of the other ways automating your procurement impacts your bottom line.

Reduced human error

Paper and manual purchase order processes quickly become chaotic. Because there’s no central tracking dashboard, each person in the chain of drafting, submitting, and approving has to keep records and create systems for task management, reminders, and follow-ups.

Fielding questions from other team members about the status of a particular order can be just as time-consuming as carrying out the order process itself and a nightmare for large, international conglomerates.

The more touchpoints a process has, the more susceptible it is to human error. As a purchase order workflow leads to a binding contract between two parties, process mistakes can be incredibly costly.

A common mistake is typos in requisition form fields like the purchase order number, the quantity of goods being purchased, or item names and codes, to name a few. These problems become even more likely if forms are handwritten instead of typed and sent electronically.

If no one catches these mistakes during the approval process, companies can accidentally order the wrong item or wrong quantity, adding significant cost. Even mistakes caught early necessitate a lot of back and forth communication between the two parties, eating up a lot of time and increasing labor costs.

Automated systems also eliminate the potential for illegible handwriting. Software automatically alerts users if information is missing from a purchase order or if there’s a typo. Some have advanced machine learning abilities that can spot significant deviations from other purchase orders issued to the same vendor, indicating the user may have made a mistake.

Turnkey procurement workflow

Purchase order software can create a smooth process for your organization from scratch.

In addition to purchase order templates, many software tools feature process wizards to map out a workflow from start to finish. This includes setting up profiles for your team members and granting them various levels of permission based on their role in the process.

You can give users authority for approval, the ability to author new purchase orders, and process viewing privileges, or you can lock them out of certain areas. You can even grant permissions for micro privileges, such as the authority to modify budgets.

Some programs allow you to limit permissions to allow only project managers to submit purchase orders to vendors, so no unauthorized procurement communications accidentally go out from your company. Creating and managing these permissions takes some time up front but quickly pays off in saved labor costs and reduced order errors later on.

More transparency

Oftentimes, one of the most time-consuming (and therefore labor-intensive) responsibilities in a purchase order process is keeping other team members updated about project status.

Ultimately, everyone is forced to work in something of a silo to keep up with the quick pace of procurement. Some people are bound to have information others don’t, which is unavoidable when no central system gleans a full picture regarding the status of every purchase order in process.

Real-time purchase order updates show the current status of every purchase order, without the need to bother someone for information.

Users can simply look at the dashboard to see which purchase orders are being drafted, which are in review, and which have been submitted and approved by vendors. They can even click to see more information about the expected delivery date and other aspects of the order.

With advanced reporting, purchase order software even tracks departmental spending in real time, so finance and accounting professionals can see how much money is left in the budget. Users can even see how much they’ve spent with different vendors, helping decision-makers spot patterns that indicate overspending or an opportunity to negotiate for better terms.

Greater flexibility

In addition to customizing permissions and authority for each user, purchase order software makes it easy to create rules about user behavior. Administrators can cap purchases at specific dollar thresholds that only the highest-authority users can override. Managers can apply these rules to specific users, vendors, items, or even the entire organization.

Users can also program conditional logic that routes purchase orders to the correct team members. For example, after an employee drafts a purchase order and submits it for review, the program can analyze its content and decide whether to send it to the employee’s direct manager or to a higher-up with authority to approve purchases in the requested budget range.

This type of automation vastly improves an organization’s efficiency, ability to uphold procurement and spending policies, compliance with contract terms, and confidence in decision-making. Over time, this translates to significant savings — and competitive advantage.

Purchase order approval workflows

Purchase orders aren’t forms that one employee can issue and execute on their own — it takes a team effort. Finance and procurement teams are in charge of allocating funds and confirming payment, and managers in other relevant departments with expense needs may need to approve purchase orders as well.

Every approval workflow has its own design, conditions, and challenges. Generally, these workflows exist inside of larger processes that are carried out regularly, such as developing marketing campaigns or paying invoices.

Purchase order approval workflows are no different. The purchase order process must integrate seamlessly with your organization’s other procurement processes and include checks and balances that protect from overspending or making bad deals.

How to create a purchase order approval process

Purchase order approval workflows vary greatly from organization to organization and even from department to department. Regardless of the procurement challenges you face in your industry, you can design a reliable review process for your purchase orders and refine it over time.

Here’s what to do.

Define purchase categories

One of the biggest challenges of setting up a purchase order approval process is that no one template is appropriate for every type of purchase your organization makes. For example, the approval process for procuring new office computers will be very different from that of buying raw materials to manufacture goods. One size does not fit all in this case.

Consider the different categories where your organization spends. Some common categories include

- Office supplies: printer paper, pens, and file folders

- IT purchases: hardware such as computers, software programs, and other expenses such as wiring or labor (sometimes included with office supplies)

- Marketing: expenses incurred from marketing campaigns, paid advertising, collateral creation, and other promotional efforts

- Other services: a catch-all for expenditures related to attorneys, parking management, third-party custodial support, and more

- Raw materials: the raw manufacturing goods your business needs to make products

Identify the most important categories for your organization. You may need to establish approval workflows for each.

Determine average spend amounts

All approval workflows need conditions to dictate whether decision-makers approve or deny a request and where they send it next for additional feedback. In purchase order approval workflows, a lot of these conditions are related to purchase amounts.

How do you decide which purchases managers should approve and which they should deny? Price limits shouldn’t be arbitrary. The best approach is to review your organization’s purchase history, including prices.

Map out this data on a bell curve to visualize the spend distribution by transaction count. This will help you build a process that flags purchase requests that are too high and helps stakeholders identify opportunities for negotiating better deals.

Establish approval hierarchies

How much purchasing authority should lower-level management and employees have? The answer differs from organization to organization, both in terms of workplace culture as well as corporate compliance. Private and public companies have different rules governing how they make spending decisions, as public companies must answer to shareholders.

Larger, more bureaucratic organizations have many stages of approvals, with most decisions escalating up the chain of command to the very top. Companies focused on efficiency usually grant more authority to lower and middle management, so they can make decisions faster.

All of these workflows — and who has approval authority within them — are usually delineated with different spending limits. For example, department managers may have authority to approve purchase requisitions or orders up to $5,000 but need oversight from their director for higher expenses.

How to streamline the purchase order approval process

Rarely will anyone find their approval process is perfect and fully optimized the moment it’s implemented. Over time, it’s necessary to improve the process to increase speed and reduce mistakes. Here are some of the most common issues.

The purchase approval process is too complicated

This is especially common in complex bureaucracies. Sometimes, an organization will design a purchase order approval process that requires review by too many decision-makers simply to avoid errors. However, this ends up overburdening management with too many documents to review, causing bottlenecks in the workflow.

To avoid this, begin by establishing a minimal workflow, and then gradually add steps to it over time as the need arises.

Decision-makers don’t adhere to the hierarchy

In small and medium-sized companies, owners and managers often have their hands in every decision. Approval workflows save them from the drudgery of day-to-day operations, so they have time to lead their companies into new phases of growth.

However, even after enacting an approval workflow that minimizes their involvement, they may insert themselves out of habit (or concern), disrupting the new system. Be mindful that the point of a purchase order approval workflow is to simplify and streamline business operations. Give it time to prove its value to break low-productivity habits once and for all.

The workflow is too labor-intensive

Every approval workflow requires decision-makers to review requests promptly. Without a set process, employees may have to remind decision-makers multiple times to review purchase orders and requisitions or figure out where to send a form for further review.

Doing this manually takes substantial time and resources from the employees responsible for managing approvals. Automation keeps the work flowing.

How Jotform Approvals can automate your purchase order process

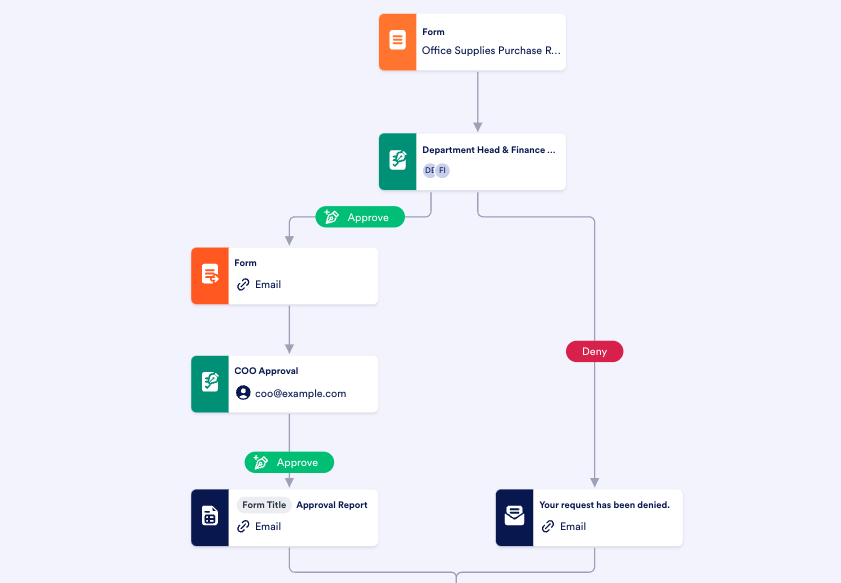

Jotform Approvals uses forms as the foundation of a smooth, automated approval workflow.

Starting with an easy-to-customize purchase requisition or purchase order approval template, you can build a streamlined workflow that automatically submits forms to managers, allowing them to approve with the click of a button. The Assign Forms feature helps you route requests to other team members for their review, feedback, or changes.

Jotform also fully automates notifications, follow-ups, and other mundane tasks that go into every approval workflow. You can even send finalized purchase orders to vendors for review directly from Jotform Approvals.

If you want a team to weigh in on a purchase order, but don’t want to sort through a tangled workflow, Jotform Group Approvals can help.

With Group Approvals, you can add multiple people to an approval and specify how many need to respond for a final decision. Once your completion rules are fulfilled, the approval flow will automatically continue.

Enterprise users can also use Jotform Teams to add a team of approvers without having to manually enter multiple email addresses.

Conclusion

Purchase order approvals are one of the most important processes in a business. The purchase order process isn’t just something finance teams have to worry about. Whether it’s buying supplies or the raw manufacturing materials central to revenue generation, procurement engages every department and team member who uses products in the course of their job.

Finding ways to streamline the purchase order approval process impacts each aspect of an organization — and each employee. Jotform Approvals is the perfect tool for building the review process and getting purchase orders to vendors as efficiently as possible. Try Jotform Approvals for free today!

Business card photo created by snowing – www.freepik.com

Send Comment: