We live in a world where nearly everything in our lives has been digitized. One key aspect is the data mobility we’ve come to take for granted.

The Pew Research Center estimates that median smartphone ownership among adults in advanced economies is 76 percent. The consumer-centric U.S. is unsurprisingly a bit higher at 81 percent. As smartphones become pervasive, the computing power we carry with us wherever we go has become more of a requirement than a luxury.

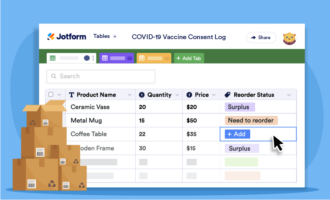

This mainstreaming of digital mobility has had a major impact on the inventory practices of product-based businesses. Organizations that skillfully adapt mobile inventory management can reduce the time products sit on warehouse shelves, fill orders quicker, and maintain smaller inventories, at reduced cost, without running the risk of not having what the customer wants when they ask for it. If this sort of “just in time” inventory management is what you seek, read on.

Understanding mobile inventory management

The focus on mobile technologies in the business world is playing out across all industries. Donna Wang, senior marketing specialist at Dynamsoft, says embracing the mobile trend is key to growing product-based businesses in the digital age.

“Adopting a mobile inventory management approach is also more economical because most employees already own smartphones, so there’s often no need to purchase additional or specialized hardware,” Wang says.

Taylor Peake, president of MotionMobs, says his company has shed outdated solutions and approaches to inventory management that hindered growth. “From retail to warehousing, the use of clunky scanners or, worse, clipboards, is a liability. These approaches result in inaccurate inventory counts, which leads to customer service issues, item loss, and stunted business growth.”

Peake says an effective mobile approach is an asset, noting that mobile solutions offer capabilities equal to inventory management systems that used to depend on desktops. “Plus, mobile solutions increase accuracy in inventory counts.”

Mobile vs traditional systems

“One significant difference between a traditional and mobile inventory management system is that traditional systems are usually implemented to support PCs or workstations,” explains Wang.

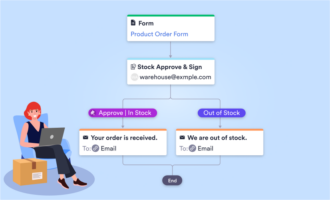

Mobile inventory management systems allow users to access the inventory database anywhere via a mobile app or a website portal. They can then easily track inventory wherever they’re working instead of from a stationary workstation far from the warehouse floor.

Peake notes that mobile devices function as barcode scanners connected to the internet. They empower employees to quickly update inventory, check prices, or search for an item on the fly. Employees don’t need to walk around the warehouse with large, cumbersome scanners that may not reliably connect to the network.

“Data gets lost with these outdated solutions,” Peake says. “Employees are already highly engaged with their mobile devices, and it’s best for the business to capitalize on this behavior instead of relying on multistep processes that include additional hardware.”

Wang also calls out the difference in order placement. Using a traditional system, inventory restocking requires manual operations, like making phone calls. With mobile inventory management, a user can place an order within an app the moment they discover low stock. The convenience factor also comes into play when employees need to search for products during a customer call.

Features to look for in mobile inventory management solutions

Specific capabilities make mobile inventory management solutions revolutionary for growing businesses. Here are the crucial features to look for.

Real-time inventory data. Authorized users can access the database from anywhere with a mobile device for accurate, real-time information. “Real-time data is critical in inventory management since there are shipments constantly moving in and out of the warehouse,” explains Wang.

Image capture. The constant stream of shipments leaving and entering the warehouse generates an enormous amount of paperwork. Wang says it’s important that images of these documents be captured and saved for proper inventory management. All you need to do that is the built-in camera on a smartphone.Location tracking within the warehouse. “It’s a huge timesaver to be able to track a particular pallet to its exact location in the warehouse. This is especially useful for large warehouses where there are hundreds of shelves and bins to manage,” notes Wang.

Send Comment: