What is inventory management? As you’ll learn throughout this guide, it’s the core of any product-based business. It’s also a process that involves ordering, storing, and making use of inventory. But there’s more to it than that — it’s about knowing when to restock certain items, how much to make or reorder, how much you should pay for goods, and more.

Key Takeaways

- Inventory management encapsulates all the processes that involve making use of inventory.

- It is used in different businesses, whether they are brick-and-mortar or e-commerce.

- Inventory management is facilitated with the technological advances, such as QR codes and barcodes.

- But still the human involvement is essential as there are many inventory management roles available.

- Jotform can be considered as a part of the complete inventory management process, thanks to its widgets and other features.

There are many aspects to inventory management that can’t be accurately covered in a few paragraphs, so we created this in-depth guide to help you master the process at your small to mid-sized business. Keep reading to learn the ins and outs.

Chapter synopsis

- Introduction

- Supply chain and inventory management. People often confuse the terms supply chain and inventory management. Learn the distinction between the two.

- Inventory management in different industries. How do inventory management practices differ between industries? In this chapter, we look at restaurants and e-commerce to find out.

- Inventory management terms. Go back to basics to learn important inventory management terms. Sure, you may have heard of them, but do you know what they mean?

- Inventory management technology. Discover several interesting technologies that help businesses of all sizes keep track of precious merchandise.

- Inventory management jobs. Is there a difference in the responsibilities of inventory managers and inventory specialists? This chapter has the answer.

- Inventory management formulas. Here, we’ll break down key inventory formulas.

- How Jotform helps with inventory management. See how you can ditch pen and paper, and keep track of inventory in a more modern fashion with Jotform, an easy-to-use form builder.

Remember to bookmark this guide for later reference. Inventory management can be a complex topic, and as your business grows, you may need a refresher on approaches or methods you didn’t find relevant before.

Supply chain and inventory management

Supply chain and inventory management are two terms that are often mentioned together, sometimes interchangeably. In Chapter 1, we defined inventory management. Below we walk through supply chain management and two other related concepts to help clarify these ideas and tie them together.

Inventory management and related concepts

Linking supply chain and inventory management

According to TechTarget,

Supply chain management (SCM) is the broad range of activities required to plan, control and execute a product’s flow from materials to production to distribution in the most economical way possible.

SCM encompasses the integrated planning and execution of processes required to optimize the flow of materials, information and capital in functions that broadly include demand planning, sourcing, production, inventory management and logistics.

It’s clear from this definition that inventory management is a component of SCM. Inventory management focuses on a specific area — namely storing, moving, and tracking goods.

“Storage is a big part of inventory management,” says Jessica Thiele, director of marketing at VL OMNI. She explains that good inventory management comes down to storing items efficiently. This means having as little inventory sitting on the warehouse floor as possible, minimizing the time products sit in storage before they’re sold, and optimizing the organization of items throughout the warehouse.

“Unproductive inventory costs your business money,” Thiele says.

David Altemir, principal and inventory management consultant at Altemir Consulting, adds that inventory management requires effective stock planning and accurate inventory counts to drive your purchasing and/or manufacturing efforts. “Poor inventory management can result in a whole series of overstocks, shortages, timing errors, and costly supplier expedites.”

Looping in inventory control

An important concept in inventory management is inventory control. Altemir explains that, in general, inventory control refers to staying on top of the physical location, cost, and quantity of each inventory item.

For companies with an inventory management system, he shares his golden rule: Your virtual reality must match your physical reality. “This means your inventory transactions must be reliably accurate and timely so your system always has an accurate picture of your inventory position,” Altemir says.

Moving into warehouse automation

The last important inventory management concept, and technological next step, is warehouse automation. According to Thiele, this concept involves creating efficiencies in the warehouse, whether it’s one you own or a third-party logistics warehouse you use. “A lot of warehouse automation concerns technology — robots on the pick-and-pack floor, AI-driven applications, full integration of all your software, and so on,” explains Thiele.

The integration piece is especially important, Thiele says, because you want data to flow automatically between applications. In fact, data integration is the first step toward automating your warehouse.

“If inventory data doesn’t flow in real time, you’re bound to have inaccuracies in item counts. Robots may help speed up movement, but they can’t pick a product that isn’t on the shelf — even if the system indicates it should be there,” Thiele says.

Her thoughts coincide with Altemir’s commentary on automation. While managers looking to cut costs often view warehouse automation favorably, Altemir notes that it can be unhelpful in certain contexts.

Success depends on the nature of your operations. Altemir says companies suffering from inventory planning and control problems won’t enjoy significant benefits from warehouse automation.

“Automation by itself doesn’t adequately address these issues,” Altemir explains, “because the fundamental limitation is actually in understanding and practicing sound inventory management principles.”

Altemir says high-volume or high-throughput companies that have solid inventory management and control will benefit greatly from warehouse automation — improving efficiency and productivity, and reducing costs.

Altemir advises companies to “remember that the vast majority of businesses are not operating at volumes comparable to Amazon or Walmart and, subsequently, should be less focused on advanced automation and more focused on their real challenge: understanding and executing inventory management best practices.”

Now that you have a firm grasp of these related concepts, we’ll move onto exploring how inventory management differs in key product-based industries.

Inventory management in different industries

While there are similarities in inventory management regardless of how it’s employed, there are a few distinctions across different industries. Below, we look at two industries where inventory management plays a leading role: restaurants and e-commerce.

Industry-specific inventory management practices

Example 1: The restaurant industry

Kyle Odom, founder of Bar Cop, says restaurant inventory management starts when a restaurant receives products from distributors. These are commonly referred to as inventory purchases. After purchases are received, they’re added to the inventory count.

There are two types of inventory control methods in a restaurant. The first type is in-and-out inventory, which is based on register rings. You’ll usually find this built into a point-of-sale (POS) system. When you ring up a drink, an order of fries, or another item in the POS, the system subtracts that product from an ongoing inventory count.

The second type of inventory management aims to prevent theft and ensure accurate ordering by tracking actual product usage, not register rings. You track inventory independently from the POS system in two main categories: beverages and food. You can break main categories down into subcategories, such as liquor, wine, bottled beer, and draft beer for beverages. “Keeping these categories separate allows for accurate calculations of beverage and food costs,” Odom explains.

You can track inventory by period — daily, weekly, biweekly, or monthly. A weekly period of Monday through Sunday is the most common. On-hand inventory is counted before the business opens on the first day of the inventory period, and then counted again after the business closes on the last day of the inventory period. Any purchases you receive during the inventory period are also included.

Odom notes that you calculate product usage during an inventory period by adding the starting on-hand inventory to purchases received, and then subtracting the ending on-hand inventory. “The final number shows how much of each product was used,” Odom explains, “by being served to customers, stolen, given away free,” wasted because of employee carelessness, and so on.

Odom points out that there’s a long history of restaurants handling inventory management with pen and paper. “Many restaurants use old eye-balling methods that are slow and inaccurate,” he says.

Employees visually guess how much product is left in a bottle, keg, container, bag, or box and count it by tenths. For example, if a liquor bottle looks half full, the employee would record 0.5 as the inventory count. “This inaccuracy leads to over- and under-ordering issues with vendors and the inability to determine whether there are any theft issues at play.”

While technology has helped eliminate the need for pen and paper, and sped up count recording, Odom says many applications still rely on employees to visually estimate counts, perpetuating the longstanding practice and count inaccuracies.

“There are a few inventory systems on the market that solve both the slowness and inaccuracy issues by weighing open products,” Odom says. “This is extremely important when inventorying beverages, as managers can better identify employee theft and other losses, providing an opportunity to remedy profit loss.”

Example 2: E-commerce

E-commerce inventory management has its own unique characteristics. Unlike with restaurants, you already have the finished goods, you’re selling them online, and you’re dealing with the time it takes to get those products to the people who purchase them.

“Order fulfillment is asynchronous — there is a significant time lag between when a customer places an order and when they receive it. This means you have to track items, ensuring they are committed to received orders and not oversold,” explains Mohammed Ali, CEO of Primaseller, an inventory and order management software solution.

In any case, products must be stored somewhere in the interim. Ali says there are three main ways this can be done:

- Store your own inventory. The standard storage method is to buy or rent a warehouse. Very small businesses may even start in the owner’s garage or a spare room in their home, then move into a larger space as they scale up. “The benefit of this option,” Ali explains, “is you maintain control of your supply chain and full privacy of your customer list — avoiding potential cut-outs by a middle man.”

- Use a third-party logistics (3PL) company. These companies are experts in inventory management. You can typically hand over inventory to them, and they will store and manage it — and often even fulfill orders — for a fee. You wind up handling only sales and marketing, and pay a rental or per-order fee, or some combination thereof. “Amazon’s Fulfilled by Amazon (FBA) is a good example of a widely used 3PL provider,” says Ali.

- Incorporate drop shipping. Here, you handle sales and marketing, and suppliers ship products directly to the customer. Ali says this option is useful for startup businesses that aren’t sure whether a product will sell, but there are much lower profit margins. “It’s less risky in some ways, like gauging product interest, but it’s more risky when considering the reliability of a supplier, the quality of products (since you never see them), and your overall brand image.”

If you choose to manage your own warehouse, efficient warehouse inventory management is a must. Ali says you need to hire the right people; know how to properly handle items; decide on an appropriate technique, such as first in, first out (FIFO); and select the right technology.

“Small business inventory management may allow for spreadsheets, but they won’t cut it after a certain point because there’s a lot of items and documentation to keep track of as you grow — customer orders, invoices, different product lines, complex item locations on the warehouse floor, multiple warehouses, etc.,” Ali says.

As for small business owners moving into larger warehouse spaces, Ali recommends asking these questions:

- What are your sales projections?

- Do you have the volume to support a larger space?

- How much space do you need for picking, packing, etc.?

- What’s your budget for a new warehouse purchase or rental?

We’ve covered a number of inventory management concepts and unique aspects up to this point. Before we get into anything more complex, let’s review some inventory management terms to solidify your knowledge base.

Inventory management terms

There can be a steep learning curve for inventory management, even if you own a product-based company that stores inventory. People tend to pick up on terminology by using context clues, but we’re going back to basics here to define common inventory management terms.

10 inventory management terms you should know

Days inventory outstanding

EOQ

Finished goods inventory

Inventory cycle count

Inventory shrinkage

Reorder point

Safety stock

SKU

Stockout

Supply chain

Days inventory outstanding (DIO) represents the number of days the current inventory will last. A lower DIO indicates a shorter time required to clear out inventory. DIO is also referred to as days sales of inventory (DSI), days in inventory (DII), or simply days inventory.

EOQ stands for economic order quantity, which is the ideal amount of a product to buy to minimize total costs related to ordering, receiving, and holding inventory. Optimizing EOQ can help minimize the amount of money tied up in inventory. We’ll walk through calculating EOQ in Chapter 7.

Finished goods inventory includes all products that have been completed by the manufacturing or production process — or that have been purchased in completed form — and that are available for sale. This term typically applies to manufacturers, since their goods can be in multiple forms, such as raw or in production. Retailers usually only maintain ready-to-sell items, meaning all their goods are finished.

An inventory cycle count is part of a company’s inventory auditing procedures. In an inventory cycle count, a subset of inventory is counted on a certain day to help maintain accurate inventory levels. Unlike a full inventory count, an inventory cycle count is less disruptive to operations — though it doesn’t offer as much accuracy across the board.

Inventory shrinkage is the difference between inventory counts recorded in accounting documents and what’s physically present in the warehouse or other storage location. For clarity, consider this hypothetical statement by an inventory manager: “According to our records, we should have 150 pillows in the warehouse, but we only have 100.” That’s shrinkage, though it’s typically measured monetarily.

A reorder point is the quantity at which you reorder an item to replenish its supply. The reorder point will differ greatly from product to product and business to business. For example, a product that sells quickly and in large amounts would generally have a higher reorder point than a slower moving product.

Safety stock refers to the extra amount of a product that you keep to mitigate the risk of stockouts. Supply and demand can shift unpredictably, and having safety stock helps ensure you’re able to fulfill orders. The benefit is that sales are uninterrupted; however, purchasing and storing extra products ties up more money in inventory.

SKU stands for stock keeping unit, which is used in conjunction with a barcode system to represent a distinct item. SKUs are typically printed on products as scannable labels and hold item-specific data such as price, manufacturer, and other product details. Businesses use SKUs to identify products and keep track of inventory levels.

As the name implies, a stockout means you’ve run out of a product. Stockouts may occur for any number of reasons: an unexpected surge in customer demand, not ordering enough of a product, an erroneous delivery from a supplier, inaccurate stock counts in the warehouse, theft, or a combination of these.

A supply chain is the network of organizations, resources, activities, and technology that works together to create, sell, and distribute products to customers. A supply chain can have many complex touchpoints, depending on things like the number or amount of raw materials involved in manufacturing a product, the type of product, and who and where the end customer is.

With terminology out of the way, let’s get into the technology side of inventory management.

Inventory management technology

The previous chapter focused on theory. This chapter focuses on application. You’re probably familiar with the scanners people use in warehouses. That’s the type of inventory management technology we cover below, along with the systems that technology connects to.

Before you dive into tech, though, be sure to brush up on inventory management best practices and inventory management techniques. They’ll help you make the most of the solutions you implement in your operations.

Hardware

Barcode

Barcode inventory management represents the first generation (1D) of innovation in keeping track of items in warehouses. Barcodes are those familiar black-and-white tags on products that are scanned in places like grocery and clothing stores.

“They afford warehouse staff significantly more accuracy and speed compared to outdated methods involving sight, pen, and paper,” says Nick Schiffelbein, CTO at LOCATE Inventory.

Schiffelbein explains that barcodes really help in the picking process, where warehouse staff must find products to fulfill customer orders. This is because the barcode system mitigates human errors stemming from sight-based selection. Instead of an employee trying to determine whether they’ve found the right product, they can simply scan it to confirm.

“This is especially useful for newer employees who aren’t sure where products are located and aren’t familiar with what products or packaging looks like,” Schiffelbein says.

QR code

QR code inventory management is the second generation (2D) of technology, improving upon what barcodes started. “QR codes achieve the same goal as barcodes — aiding in locating and tracking products — but offer more capabilities,” says Schiffelbein.

The main advantage of using QR codes instead of barcodes is their ability to store more data. Since these codes use dots and squares of varying size and position instead of a static series of bars or vertical lines, QR codes offer more scanner flexibility and space. While a barcode typically holds only 20 to 25 characters, QR codes can hold up to 2,000.

RFID

Short for radio frequency identification, RFID inventory management is often considered the third generation (3D) of technology. While it still requires physical tags similar to barcodes and QR codes, RFID has a key difference: You don’t need line of sight to scan tags.

Barcodes and QR codes require you to not only be close to the tag but to have a direct line of sight with your scanner. In contrast, RFID tags can be scanned from a distance — up to 20 meters away, depending on the system and hardware you use. Plus, you can scan multiple items at once, instead of one at a time.

So what’s the catch — why doesn’t every business make the switch to RFID? Schiffelbein explains that “RFID inventory management is certainly cutting edge, but it’s simply too expensive. The cost is a huge barrier to entry for small businesses, and even larger businesses are hard-pressed to justify the spend.”

Software

The hardware above typically ties in with a software solution that may be on the premises, in the cloud, or a hybrid of the two. The size and complexity of your business will dictate the type of solution you choose. For example, if you’re just starting out and sell only a few products, you may stick to a simple spreadsheet.

In contrast, if you’re scaling up or running a larger business that sells many products, you’ll need a more robust solution. There are a number of options available. Check out our blog post for a handful of inventory management software systems that range from simple to advanced.

Another thing to consider regarding technology is mobility. The modern workforce is getting more mobile, and professionals in inventory management are no exception. When considering solutions, ensure mobility is one of your criteria. You can start with the solutions in our blog post which include supplemental inventory management apps.

We’ve discussed technology. Now let’s talk about the people who use it. Keep reading to learn about what it takes for warehouse staff to keep things running smoothly.

Inventory management jobs

It takes more than technology to keep the warehouse stocked and inventory counts accurate. People still have important roles to play — tech just helps make those jobs easier. Below we cover three such jobs. Though they have similar titles, their responsibilities, while sometimes overlapping, are distinct.

Inventory manager job description

Inventory managers often oversee product management and distribution. They’re accountable for meeting defined inventory goals, managing inventory systems, and acting as liaisons to other departments.

According to Indeed, these are a few of the responsibilities you can expect an inventory manager to handle:

- Ensuring accurate product inventory for clients

- Managing an inventory tracking system to streamline business operations

- Communicating with the warehouse manager about current stock and potential issues with orders

- Conducting daily analyses to forecast potential inventory issues

- Reporting on inventory activities and variances to senior management

- Assessing new inventory to ensure it’s ready for shipping or delivery

- Continually developing, refining, and implementing inventory control procedures and best practices

Qualifications can vary based on the rigor of inventory practices and the business’s needs. Here are some examples:

- Bachelor’s degree in business, finance, or a related field

- 5+ years’ experience in inventory, distribution, and operational procedures

- 2+ years’ supervisory experience

- Excellent knowledge of data analysis and forecasting methods

- Ability to multitask and work independently

- Proven leadership skills

- Excellent written and verbal communication skills

- In-depth understanding of distribution workplaces

Inventory control manager job description

Some companies use the titles inventory manager and inventory control manager interchangeably, meaning the job descriptions often appear nearly identical. However, responsibilities for inventory control managers typically align more closely with inventory control practices — keeping accurate inventory counts, as well as achieving objectives for loss prevention and optimized inventory spaces.

By comparison, inventory management has a broader focus on managing demand through forecasting and ensuring warehouses are stocked with the right quantity of inventory.

Payscale job descriptions for inventory control managers tend to include these responsibilities:

- Establishing and monitoring inventory minimum/maximum levels

- Directing and planning the organization of facility inventory for efficient material storage and handling

- Assisting with organizing and reviewing bills of material for accuracy and requesting internal change orders to correct discrepancies

- Implementing and executing inventory replenishment processes to ensure proper stock levels

- Acting as liaison between departments to identify obsolete stock and optimize inventory turnover

- Performing audits and cycle counts as scheduled and as needed to maximize inventory accuracy

Qualifications resemble those for inventory managers, with a few differences:

- Bachelor’s degree in business, finance, or a related field

- 3+ years’ experience in inventory control, specifically in a SKU-intensive environment

- Working knowledge of inventory management software

- Ability to accurately track inventory and create reports

- An analytical mind with strong math skills

- Excellent organizational and planning skills

- Outstanding communication and interpersonal abilities

Inventory specialist job description

The inventory specialist differs from the preceding two roles in that it’s typically a non-managerial position that reports to and supports one or both of the other roles. Depending on the organizational structure, an inventory specialist may supervise subordinate warehouse staff.

Glassdoor notes several typical responsibilities for inventory specialists:

- Inspecting returned merchandise

- Tracking incoming and outgoing products

- Providing inventory control reports as required

- Maintaining count accuracy (digital and physical counting)

- Updating database with incoming and outgoing products

- Loading and unloading deliveries

- Disposing of obsolete inventory as directed

Qualifications for inventory specialists are noticeably less stringent than the managerial roles described above:

- Associate’s degree in business or related field

- 2+ years of experience in an inventory role

- Ability to use a computer and other office technology

- Familiarity with inventory management systems

- Ability to lift up to 50 pounds

- Ability to stand and bend for long periods of time in a warehouse environment

- Great written and verbal communication skills

- Experience with budget management

- Attention to detail to identify defective products or damaged packaging

These are key roles that help keep any warehouse running smoothly. Now we’ll move onto several critical inventory management formulas.

Inventory management formulas

Inventory is all about numbers — how many products you have in stock, how many products you need to order next month, how much your on-hand inventory costs, and so on. And where there are numbers, there are formulas.

Inventory turnover formulas

According to Investopedia, inventory turnover is a ratio that indicates how many times inventory has been sold and replaced during a given period. This ratio helps with decision-making for pricing, marketing, and other strategies. The formula is as follows:

Inventory turnover = sales / average inventory

Sales is self-explanatory, while average inventory can be found using this formula: average inventory = (beginning inventory – ending inventory) / 2. “It’s important to point out that this calculation only applies to inventory turnover for finished goods,” explains Altemir.

Using sales to calculate inventory turnover inflates the result because the sales number includes a markup. That’s why there’s an alternative inventory turnover formula that uses the cost of goods sold (COGS):

Inventory turnover = COGS / average inventory

COGS represents the direct costs of producing goods, including material costs and production labor. Using COGS in place of sales provides a more accurate picture of inventory turnover.

In either case, the use of average inventory mitigates the impact of seasonality. In many industries — especially retail — sales and inventory can experience large fluctuations such as during year-end holidays when consumers are more prone to shop.

Altemir adds that, for manufacturers, it’s useful to understand the underlying components of finished goods, namely raw material turnover. “Performing a deeper analysis of the direct material cost of the products — i.e., taking more care in formulating the numerator of the equation — results in greater accuracy.”

EOQ formula

Back in Chapter 4 we noted that EOQ refers to the ideal amount of a product to buy to minimize total costs related to ordering, receiving, and holding inventory. Investopedia provides the formula for EOQ:

Q = √(2DS/H)

Here are the definitions of the variables:

- Q represents EOQ units

- D represents demand in units (usually on an annual basis)

- S represents order cost (per purchase order)

- H represents holding costs (per unit, per year)

In layman’s terms, the formula considers the timing of reordering (D), what it costs to place an order (S), and what it costs to store products (H). The result of the equation (Q) tells you when to reorder a given product to avoid running out of inventory. While there’s an immediate opportunity cost in lost revenue due to a shortage, there’s also the possibility of losing the customer altogether.

The EOQ formula assumes consumer demand, along with ordering and holding costs, will remain constant. This is why Altemir cautions against relying too heavily on EOQ for purchasing decisions. He says the theory is sound but putting it into practice is a different story.

“Knowing exactly what your cost per transaction and holding costs per unit are with any degree of fidelity is difficult. There are better ways to decide how much to buy (or make), such as using customer demand and other practical considerations,” Altemir says.

Inventory management Excel formulas

Unless you have an inventory management system in place, you’ll likely be using Excel to keep track of inventory. But even if you do use a more robust system, Excel still comes in handy for calculating inventory-related formulas. Altemir suggests these tried and true ones:

- SQRT(). As in the EOQ formula, you’ll sometimes need to use the square root function to complete an equation.

- AVERAGE(). You can use this function to quickly determine average inventory when calculating inventory turnover.

- STDEV(). The standard deviation function can help calculate safety stock.

- +, -, /, and *. “Basic addition, subtraction, division, and multiplication are often all you need in your day-to-day routine,” says Altemir.

Excel and other spreadsheet solutions are always handy in inventory management. Up next, we’ll cover another great addition to your inventory management toolbox: JotForm.

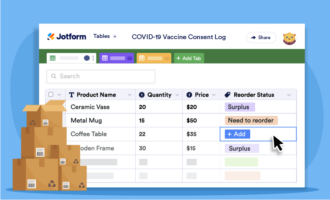

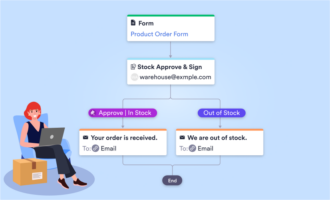

How Jotform helps with inventory management

Whether you’re looking to replace outdated pen-and-paper practices or supplement a spreadsheet-only solution for keeping track of inventory, Jotform can help. The easy-to-use form builder lets you quickly and accurately update important inventory information, such as product name, quantity on hand, and unit price.

With Jotform, you can keep track of a wide array of items:

- Office supplies

- Restaurant supplies

- Food and beverages

- Furniture

- Pet products

- Equipment

Jotform + inventory management

Inventory widget

The inventory widget tracks the quantity of a single item, such as a dog bone. Start by configuring the total number of items for sale — let’s assume 100 for an easy math example. You can then add the order form to your website.

Each time a customer makes a purchase and submits the order form, the number of items they purchase is deducted from your inventory count. For example, if a customer purchases three dog bones, your inventory will be reduced to 97.

Sell more than one item? You can add an inventory widget for each item you sell. That means a widget for dog beds, a widget for cat scratching posts, and a widget for every other fun product in your pet arsenal. (Of course, the same concept applies for non-pet businesses!)

This widget is great for limited subscriptions, small online stores, and limited-item inventory management.

Barcode scanner

If you’ve incorporated barcodes into your warehouse operations, our barcode scanner widget is the perfect addition to your forms. No need for cumbersome, expensive equipment your staff will have to lug around the warehouse floor — you can use the devices you already have, like your computer, tablet, or smartphone.

Once you add the barcode scanner to your form, you can use your device to capture barcodes on whatever product is in front of you. The widget then converts the information stored on the barcode to readable text and displays it on the form.

Inventory management templates

Jotform includes a number of inventory templates you can use in your daily operations. Simply fill in the information, and you can convert the results into a polished PDF you can view, download, or print.

Every template is customizable through an easy, drag-and-drop PDF Editor. Start with a template you like, then add or remove fields as needed. Add your company logo and colors to match your branding. You can even add signing capabilities through our e-signature widget to hold staff accountable for their inventory activities.

Here are a few templates you can start with:

- Inventory checklist. Performing an inventory audit on your products? Use this checklist to ease your quality control efforts. The template includes fields like area, condition, and quantity.

- Office supplies inventory. Need to keep track of more than a few pens and staplers? Start with this form, which includes fields like item description, quantity to be ordered, and signature.

- Beverage inventory. Keep track of your liquor with this handy form. It includes fields like liquor brand, size, weight, and unit price. Quick tip: Add more descriptive categories or a text box for spills, bottle breakage, and theft.

Ready to upgrade your inventory management practices? Get started with Jotform today.

More about your inventory management guides

Mohammed Ali

Mohammed Ali is the CEO of Primaseller. He has more than 13 years of experience in the operations and supply chain functions for a diverse set of industries, including food commodities, office supplies, and home and living. At Primaseller, he talks to retailers across the world about optimizing their inventory and supply chains, particularly in the context of omnichannel retail.

David Altemir

David Altemir is principal and inventory management consultant at Altemir Consulting, an operations management consulting firm in Dallas, Texas, that focuses on manufacturing and distribution. He has more than 25 years of experience instituting transformational improvements across numerous industries, including medical products, aviation, and food manufacturing. He is also the author of Lean MRP: Establishing a Manufacturing Pull System for Shop Floor Execution Using ERP or APS.

Kyle Odom

Kyle Odom is a proud husband and father, and the founder of Bar Cop. He is dedicated to formulating valuable inventory management strategies for the hospitality industry.

Nick Schiffelbein

Nick Schiffelbein is the chief technology officer at LOCATE Inventory, a cloud-based inventory and order-management software solution designed to help companies in both the warehouse and e-commerce space. The company is headquartered in Orange County, California.

Jessica Thiele

Jessica Thiele is the director of marketing at VL OMNI, an iPaaS point-to-multipoint, serverless, data integration platform that captures business rules for a fully automated supply chain and technology stack.

Send Comment:

2 Comments:

More than a year ago

Thanks for sharing

More than a year ago

After taking operations and supply chain management class during my masters, I knew that coming from an analytical background, that was the right choice for me. It always fascinated me how a simple formula can save millions of dollars to a company.

I started as a supply chain management intern at a large printing & packaging company. Seeing the theoretical stuff work in real life gave me the necessary satisfaction and motivation to try to be better at what I am doing. That is why even though I was an intern, I was looking for ways to even enhance the current operations.

I have a very good buddy who is working in an animal shelter and he was talking about how using online forms with the e-signature widget speeds up the approval process in their organization. Knowing that even small amounts of time saved in my area of work could lead to very effective outcomes, I wanted to give it a try. I introduced online forms to my supervisor, as we kept using it we started seeing the benefits and how cost-efficient it made us. Thanks to that I am now a full-time employee at my company. I'll always try to keep trying to find new ways and not going to be afraid of stating my ideas :) That's why I love my line of work!